Raise Your Specifications: Introduction Excellence in Material Testing Lab Solutions

Wiki Article

From Raw Materials to Final Products: The Duty of Product Screening Laboratories in Ensuring Quality and Dependability

Product screening research laboratories play a vital duty in this process, from assessing raw materials to assessing the last products. By carrying out various tests, these laboratories guarantee that the products utilized fulfill market standards and conform with regulations. From examining the strength of steels to evaluating the make-up of plastics, material screening laboratories supply valuable understandings to manufacturers and assist them supply top notch items.Significance of Product Testing in Top Quality Assurance

One of the primary reasons product screening is crucial for quality guarantee is that it aids you determine whether the materials fulfill the called for requirements and requirements. With extensive testing, you can verify if the products have the preferred mechanical, chemical, and physical buildings. This makes certain that your items will certainly perform as desired and fulfill the expectations of your consumers.

Additionally, material screening helps you recognize any possible security hazards related to your products. By examining for elements such as flammability, poisoning, or electric conductivity, you can guarantee that your items comply with safety regulations and criteria. This not just safeguards your consumers but additionally safeguards your reputation and lessens the threat of obligation.

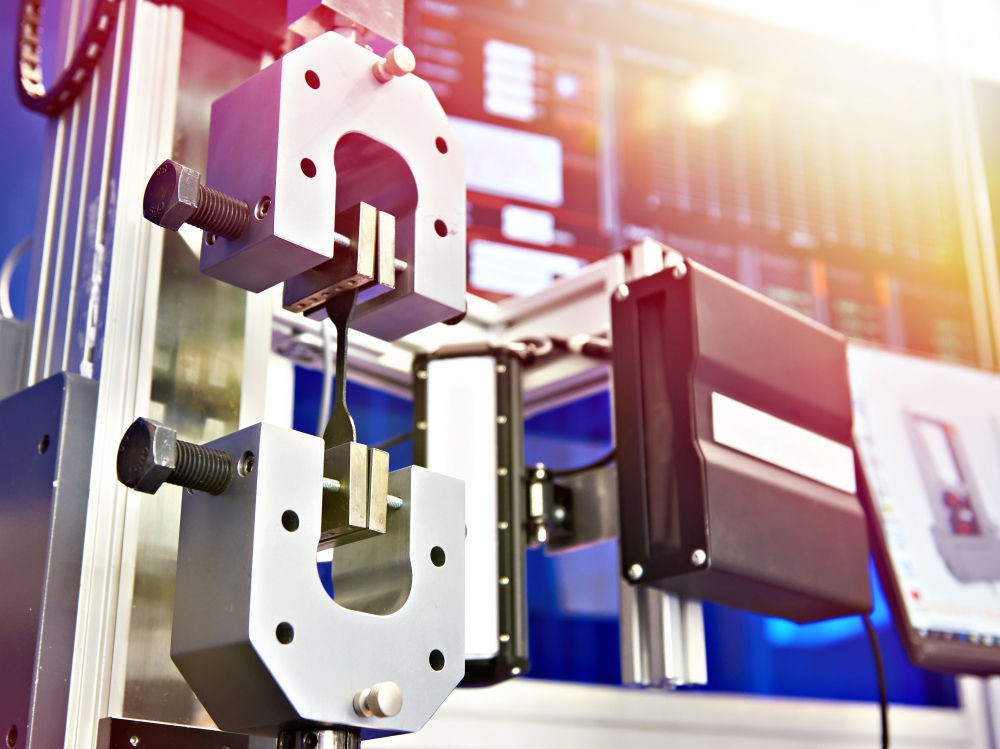

Types of Examinations Performed by Material Testing Laboratories

To make sure quality and dependability, product testing labs conduct a range of examinations on raw materials and completed items. Material screening research laboratories likewise perform impact examinations to evaluate a material's capability to withstand unexpected shock or influence forces. By carrying out these examinations, material screening research laboratories guarantee that the raw products and completed items meet the called for requirements and specifications, guaranteeing high quality and integrity in various industries.Function of Material Screening in Ensuring Item Integrity

By analyzing the physical, mechanical, chemical, and electrical residential properties of materials, material testing makes sure the integrity of products. With a collection of strenuous tests, material screening research laboratories are able to identify any prospective weak points or flaws in the materials utilized in the manufacturing procedure.

Product screening helps to identify whether the products used in the production of an item meet the needed specs and standards. It helps to identify any kind of problems or variances that might influence the efficiency or sturdiness of the end product. By subjecting products to numerous examinations, such as tensile strength, hardness, corrosion resistance, or flammability, product screening makes certain that the products used appropriate for their desired application and can hold up against the conditions they will certainly be exposed to.

In addition, product screening allows suppliers to review the performance and dependability of their items under various ecological conditions. By simulating real-world situations, such as severe temperature important site levels, humidity, or resonances, material testing assists to determine any kind of possible weaknesses or susceptabilities that might affect the item's efficiency or lifespan. This permits producers to make needed renovations or adjustments to ensure that their items satisfy the highest requirements of quality and reliability.

Sector Requirements and Product Screening Conformity

Ensuring conformity with market criteria for material screening is critical in preserving the top quality and reliability of items. These sector criteria offer as standards that define the minimum needs and specifications for screening products used in numerous markets. By sticking to these criteria, manufacturers can guarantee that their items fulfill the required quality and security standards.Material screening labs play a crucial duty in making certain conformity with these industry criteria. These laboratories are equipped with state-of-the-art devices and use skilled professionals who are fluent in the testing treatments needed for various products. They perform a variety of tests, such as mechanical, chemical, and physical examinations, to assess the residential properties and characteristics of materials.

Adhering to industry criteria aids suppliers satisfy customer assumptions and regulatory needs. It likewise aids in stopping product failings and recalls, which can bring about monetary losses and damages to the track record of the firm. Additionally, adherence to these standards advertises fair competition among makers, as it guarantees that all products satisfy the very same high quality requirements.

Product screening conformity likewise plays a considerable function in international profession. Several nations have their own set of industry standards, and conformity with these requirements is usually a requirement for importing and exporting products. By guaranteeing conformity, manufacturers can increase their market reach and establish themselves as trusted distributors in the worldwide market.

Benefits of Partnering With a Product Testing Laboratory

When partnering with a material screening laboratory, you can profit from their proficiency and modern equipment to make sure the quality and dependability of your items. Product testing labs utilize very competent specialists who have considerable knowledge of different materials and screening approaches.

Additionally, material testing research laboratories have advanced devices and innovation that can properly assess the residential or commercial properties and attributes of your products. They can perform a broad variety of examinations, consisting of mechanical, chemical, and thermal examinations, to evaluate the performance and sturdiness of your products. By partnering with a material testing lab, you can make sure that your products satisfy or surpass market requirements and regulative demands.

One more benefit of partnering with a material testing laboratory is the ability to identify and address possible concerns prior to they end up being major issues. Through extensive testing and analysis, these research laboratories can identify any kind of issues, weak points, or disparities in your materials. This allows you to make informed choices and take rehabilitative activities to enhance the high quality and dependability of your products.

Verdict

In final thought, material testing research laboratories play an essential duty in guaranteeing the top quality and reliability of final items. Partnering with a material testing research laboratory offers many advantages, including enhanced item performance, customer contentment, and compliance with guidelines.Product testing labs play a crucial function try this out in this procedure, from analyzing raw materials to assessing the last products.To make sure quality and dependability, product screening laboratories carry out a variety of tests on raw products and ended up products. By carrying out these examinations, product screening laboratories make look at this site sure that the raw products and completed items satisfy the needed criteria and requirements, assuring quality and dependability in numerous sectors.

By subjecting materials to various examinations, such as tensile strength, firmness, corrosion resistance, or flammability, material testing makes certain that the materials utilized are appropriate for their designated application and can stand up to the problems they will be subjected to. - material testing lab

Material testing laboratories employ very experienced professionals that have comprehensive knowledge of various materials and screening methods.

Report this wiki page